Making a Spoilboard and Breaking Things

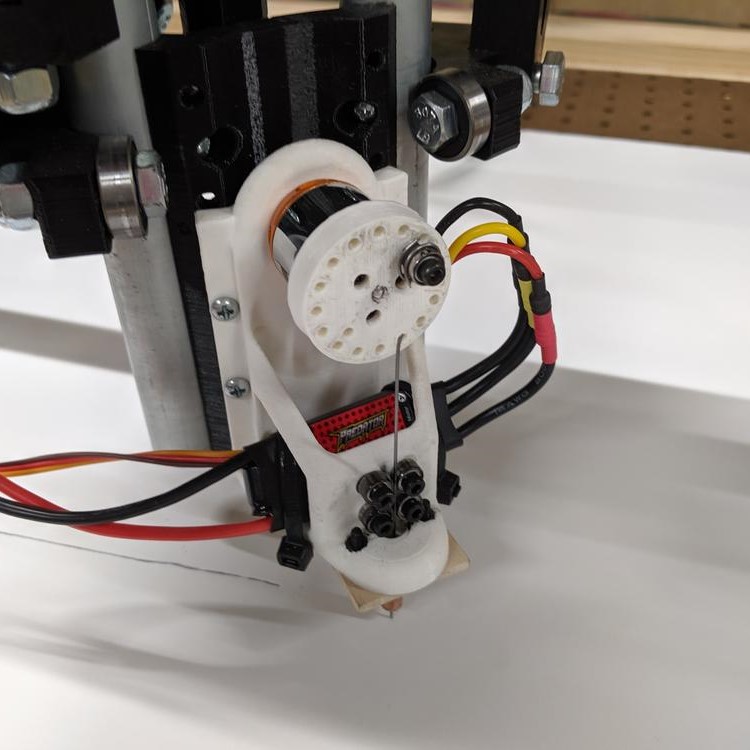

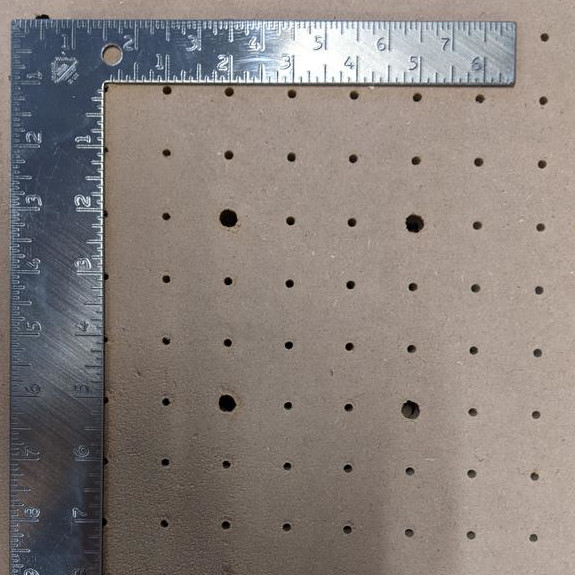

In the process of creating a spoilboard for the MPCNC, I came across several lingering issues with the machine that needed to be resolved. It ended up being an opportunity to correct a bunch of broken bits, tighten up nuts and bolts that had loosened, and come to terms with an accuracy problem I had been ignoring.

This project also gave me a chance to try a new method of documentation, and learn a lot about what works and doesn’t work for my creative workflow.